ODM/EMS/CASE

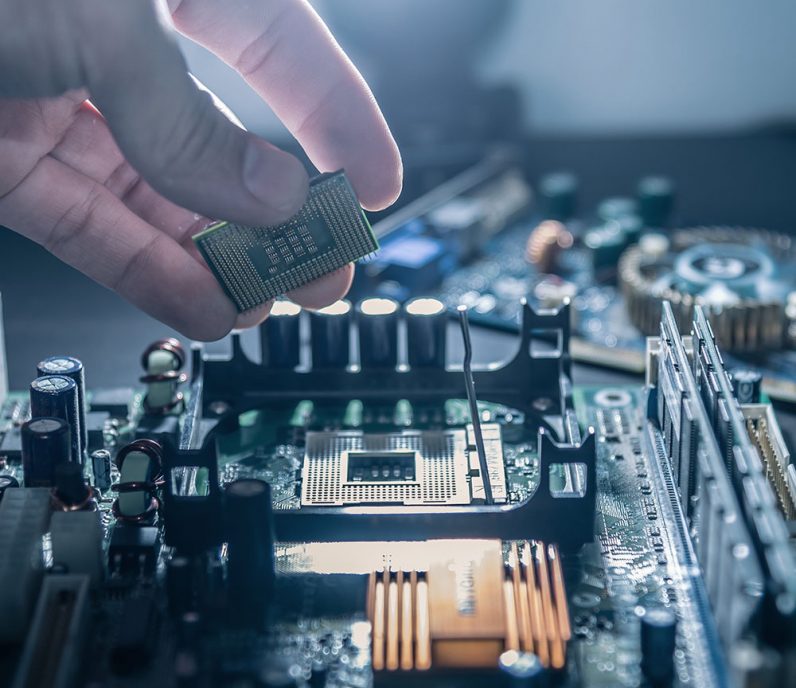

Original Design Manufacturing Process

ODM and EMS Processes

Analysis of Requirement / Preparation of Specifications

Electronics Manufacturing Services

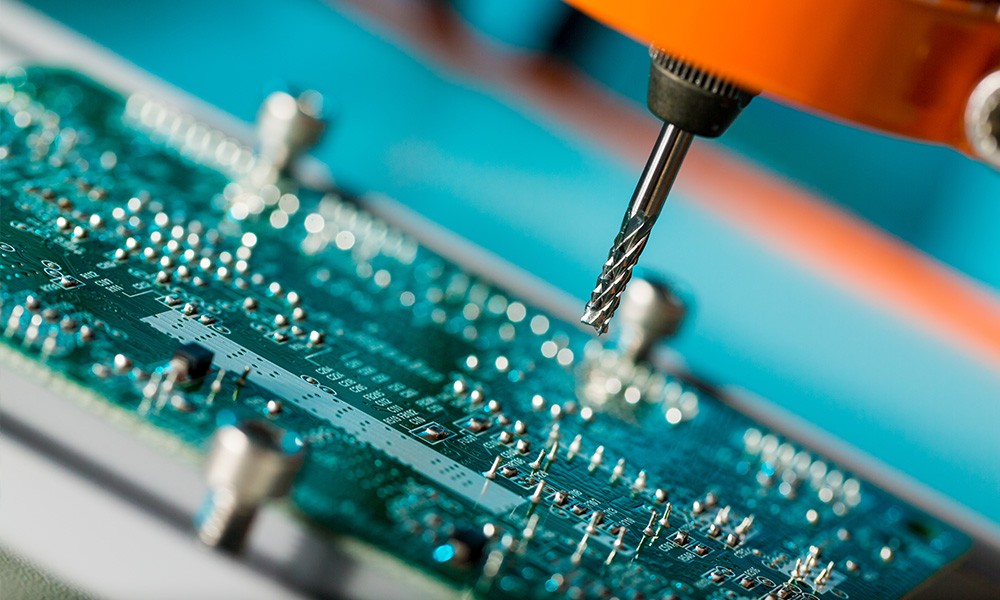

The latest manufacturing services of Ecotronix offer competitiveness through saving costs of customer companies and providing reliable products that can quickly respond to the market.

The measure of small quantity batch production provides an end-to-end solution from PCB Assembly to the manufacturing measure of final products.

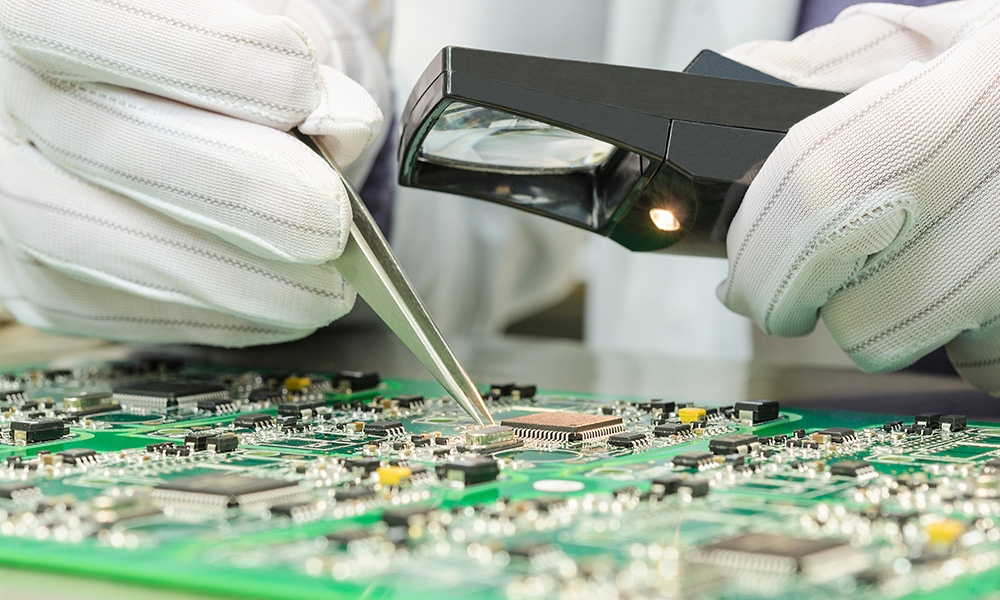

It is provided as an integrated service including features such as a wide range of integrated design, engineering, assembling, and distributing depending on the needs of customers from advanced communication devices to various IoT devices, industrial control equipment, medical devices, etc.

Benefit for EMS Service

The EMS process of Ecotronix seeks to improve the manufacturing quality by establishing an end-to-end traceability system through a real-time history tracking system through features such as RFID while implementing a Smart Factory through the employment of a real-time process control system in each sector and operating in an efficient response system.

EMS Process

Electronic Manufacturing Service