EXCELLENCE

IN

MANUFACTURING

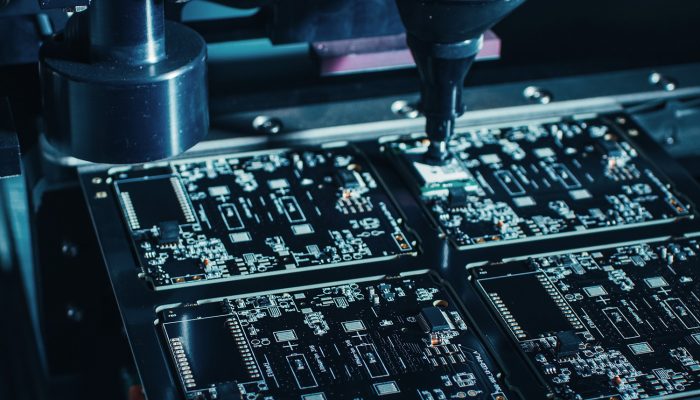

Low Volume High Mix

Production Process

We are operating a small quantity batch production system in order to respond to the various needs of consumers. The production lines are operated with cell lines to be enable multiple items to be produced at once. We maintain a consistent production and quality control through the All-in-one production system from SMT to the final packaging/shipping of products. 4M, changes in design, and the application of the latest process technologies follow a standardized process and can quickly reflect the needs of customers.

Real Time Process Monitoring System

We are implementing a smart factory through a real-time manufacturing process tracking system, which enables real-time tracking and monitoring of all phases from the warehousing of parts to the whole manufacturing process, quality inspection, and the final shipments. All data collected from each step allows immediate responses in case of errors through automatic monitoring of real-time performance analysis and process information.

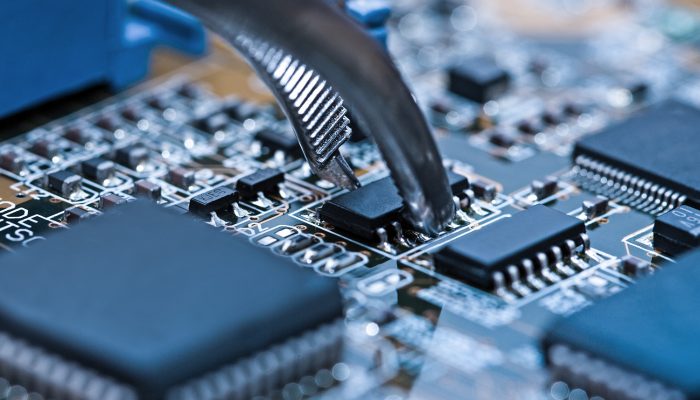

Qualified SMT Capability

ECO SMT is capable of responding to the mounter of extremely small parts such as 0402 and is managed by special environmental management measures on features such as temperature/humidity/static power/vacuum state/nitrogen levels to ensure the reliability of manufacturing processes. Furthermore, working conditions such as the optimal temperature profile for the best soldering quality is provided by according to product models. To prevent insertion errors, RFID tracking systems are applied to the mounter components and results are thoroughly managed through advanced AOI, SPI, etc.